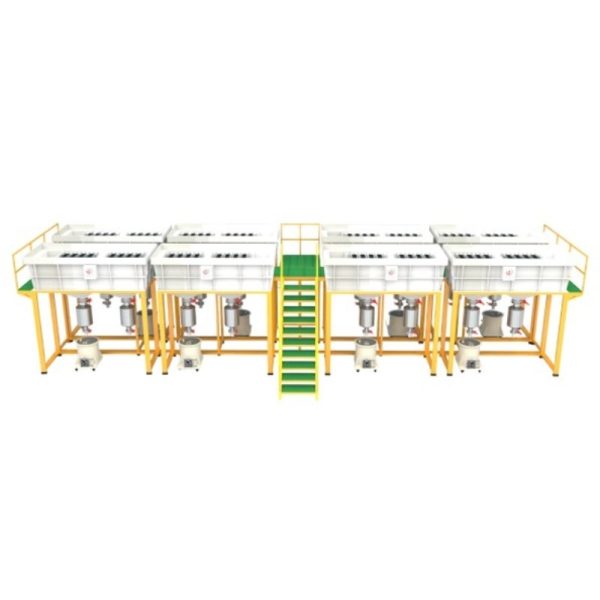

Silver Electrolysis Refinery Plant

Introduction:

Our Silver Electrolysis Refinery Plant employs cutting-edge electrolytic refining technology to achieve the highest purity silver with exceptional efficiency.

Refining Process:

- Dissolution of Silver Anodes – Silver is dissolved in a nitric acid bath to initiate the refining process.

- Deposition of Pure Silver – High-purity silver is deposited onto the cathodes.

- Separation of Impurities – Copper and other soluble metals dissolve into the bath as nitrates.

- Retention of Valuable Metals – Gold and other insoluble metals are collected as a sponge on the anodes.

- Final Purity Output – Produces 99.9%+ pure silver, meeting the highest industry standards.

Key Benefits:

- High Purity Output – Consistently refines silver to 99.9% or higher.

- Efficient Process – Maximizes recovery while minimizing waste.

- By product Recovery – Extracts valuable metals like gold and copper.

- Eco-Friendly Operation – Reduces environmental impact with optimized chemical usage.

- Low Maintenance – Designed for long-term durability and minimal upkeep.

This advanced refining solution ensures cost-effective, high-quality silver production while recovering valuable by-products, making it an ideal choice for precious metal refiners, jewellery manufacturers, and industrial applications.

You haven't viewed at any of the products yet.